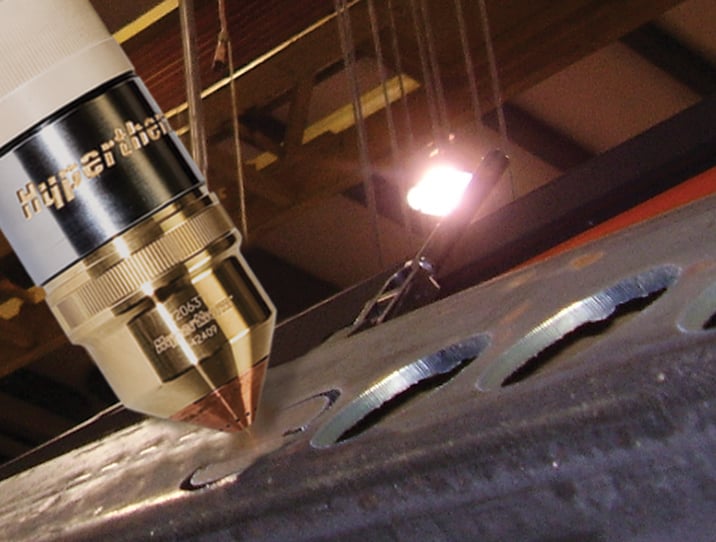

LongLife plasma cutting systems

Ideal for production environments cutting mild steel, stainless steel and aluminum, our heavy-duty air and oxygen LongLife systems are cost-effective alternatives to oxyfuel or single-gas air plasma systems. Hypertherm’s patented LongLife® technology dramatically improves consumable life for both oxygen and air processes.

Features and benefits

-

LongLife technology provides maximum consumable life for high capacity automated cutting applications.

-

The need for minimal secondary operations can provide maximum productivity, significantly reducing operating costs.

-

LongLife air and oxygen plasma systems offer impressive cut speeds and pierce times up to 7 times faster than oxyfuel.

-

Exceptional reliability is a hallmark of Hypertherm’s LongLife air and oxygen plasma cutting systems.

Explore LongLife solutions

Plasma bevel cutting

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

Plasma hole cutting

Many fabrication processes require cutting holes to bolt two or more pieces or parts together, so hole production is an important part of most cutting operations. Multiple holes can be cut into a large plate, pipe, or drum with plasma.

Plasma gouging

Plasma gouging – removing metal using a plasma arc – is similar to plasma cutting. A plasma arc between the torch and the workpiece melts the metal, and a gas jet blows away the molten material.

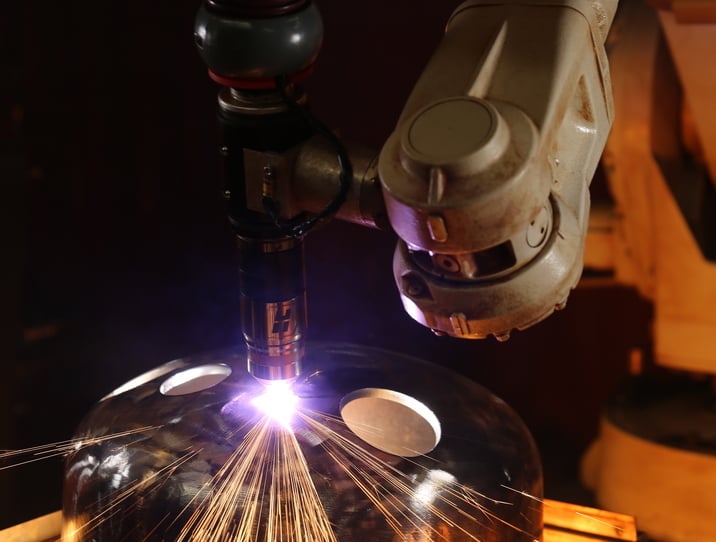

Robotic plasma cutting

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.