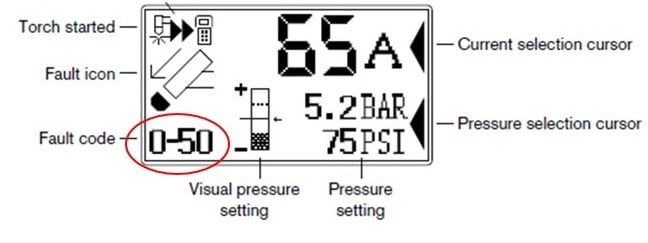

Number 4: Counting down the five most common Powermax fault codes, 0-50

Numeric fault codes are there to keep your Powermax plasma system operating at peak performance, but more importantly some of these codes are there to protect you and keep you safe. That’s just the case with a 0-50. Even before you notice this fault code on the LCD status screen of your Powermax65, Powermax85, Powermax105, and Powermax125, the power supply shuts off automatically, shifting into safety mode to prevent electrical shock. This mode puts the power supply into lockdown, protecting the operator.

Like all fault codes, the 0-50 will be visible in the lower left corner of the status screen on the power supply, but what does it mean and how is it fixed? This code involves the spring-loaded sensor switch in the torch body (photographed below). It means this switch isn’t engaged. This fault most often involves the retaining cap, used to push the switch in and turn the power on. If the retaining cap is not threaded-on completely, the switch can’t close.

You’ll need to clear this fault code before the Powermax system will power-on again. Here’s a list of things to do to clear this code:

- Did you just change your consumables? If yes, first try repowering the system by turning the power switch off, wait a couple of seconds and then turn it on again. If the code is gone, you can begin cutting again.

- If the 0-50 remains on the screen, turn the power supply off again. Check your retaining cap. Is it snug and properly aligned? Many times, the retaining cap is just loose, so tightening it could immediately fix the problem and clear the code. However, don’t over tighten it.

- Next, try removing the consumables from the torch. Look to see if you have the right consumables installed. If needed, change the consumables.

- If you have the right consumables for the job, examine them for surface damage. Then replace damaged or worn consumables and reload the torch to see if that clears the code.

If the consumables are in good working order, but the code remains on the screen then the torch might be damaged. Remove the torch from the power supply and try another torch that is known to work. If you don’t have an extra torch to test, then look at the torch lead plug-in and test the electrical resistance between pin 5 (the cap-sensor switch) and pin 7 (common, note it is shorter than 5 by design) with a multimeter. Put the multimeter into the ohms setting. If you get a high reading when testing the pins, then that means you have a broken wire or a bad switch. The easiest solution is to buy a new torch, but consult an authorized distributor since a replacement switch is more affordable.

Check back next Friday as the countdown continues. That’s when we reveal the third most common fault code operators ask us to explain. Click here to read Number 5 on the list.