Powermax profitability: 6 factors for calculating total cost of ownership

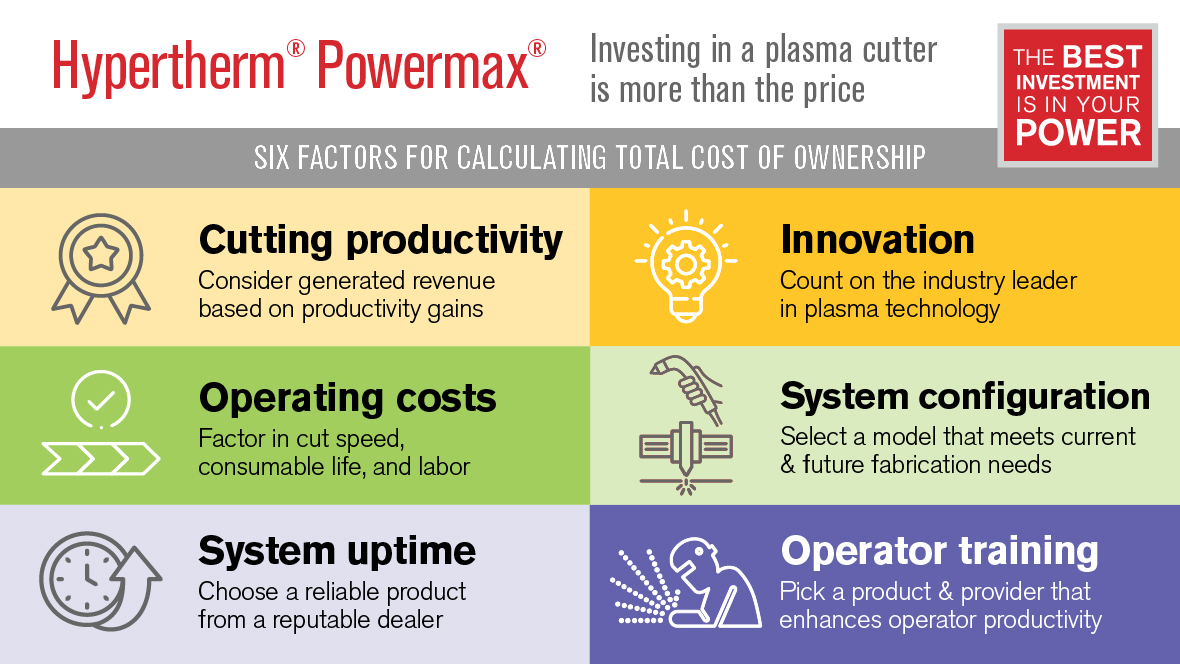

Before investing in equipment, you may want to calculate the total cost of ownership (TCO). When considering the purchase of a portable plasma cutting system, especially one of premium performance and quality like Hypertherm Powermax®, calculating the TCO will help you make an informed purchase decision and provide insight into profitability.

Experienced metal fabricators and managers know precise budgeting must account for more than the initial cost. The purchase price of a plasma cutter is only the first of considerations―the least expensive plasma cutter may cost more in the long run. A TCO analysis can sometimes involve a complex review of various factors; however, when considering the purchase of a portable plasma cutting system, there are only six main factors. Other times, there are hidden aspects of ownership or additional costs that are easy to overlook or forget altogether. Planning for these overlooked factors is the best way to ensure your cutting operations are cost-effective and there is a fast return on your investment.

Profitability factor 1: cutting productivity

Your TCO can be greatly impacted if cutting productivity isn’t a key variable in the calculation. For instance, it will cost you if you select a portable plasma system that’s not entirely up to the job or a specific application to save a little money upfront. And those production costs will add up sooner than you think.

When selecting a plasma system, it’s essential to consider the return you expect to receive on the investment and the revenue the plasma system can generate based on its productivity. Suppose one properly selected and robust plasma system can do the work of two or three lesser plasma systems during its operating lifespan or an alternative technology that is less suited for the task. In that case, you’ll start seeing those savings quickly. The cut performance over the life of the consumables will also significantly impact productivity and operating costs. Powermax systems have the most prolonged and consistent cut quality over consumable life, resulting in higher productivity.

Profitability factor 2: power supply uptime

While there are ways to save money when purchasing a plasma system, it’s important to consider the service that comes with the equipment. Even if you save some money upfront by getting a plasma system from a less preferred provider, you’re gambling those savings with the support you can expect on an ongoing basis. When your equipment goes down or needs maintenance, your profits go down. And, in this business, it’s hard to avoid an occasional mechanical setback.

Choosing an industry-proven, reliable plasma system and a reputable dealer makes all the difference. Hypertherm Associates has a worldwide network of qualified partners with service and support centers ready to keep a Powermax plasma system operational and get you up and running again as soon as possible if the equipment does go down. You can’t get that kind of service if you buy a low-cost portable plasma system from many big box stores or online sellers.

Profitability factor 3: plasma cutting operating costs

The operating cost of a plasma system is significant to the TCO. Some might think that calculating the cost of cutting is complicated and, if done correctly, must consider many factors. However, an effective TCO methodology needn’t be complex. To determine a realistic operating cost when comparing plasma systems, one should look primarily at two components―the cost per hour of work and the number of meters or feet a system can cut in an hour. To do this, you’ll need to know: 1) the total number of arc hours for a set of consumables or a cartridge (from the manufacturer), 2) the cost of the consumables or cartridge, 3) the duty cycle of the system, and 4) the amount of cutting than can be done in an hour factoring the duty cycle (percent of time the system can operate in an hour) and the cut speed for the metal thickness being cut. With this information, one can determine the cost of a meter or foot cut by factoring in the labor rate of the operator.

Profitability factor 4: plasma cutter technology

Most of the technological innovations in plasma cutting over the past 50 years have been developed by Hypertherm Associates. With over 100 plasma technology patents, we lead the way in bringing to market customer-focused solutions and product functionality that:

-

Provide the most extended torch consumable/cartridge life to lower your overall cost of operation

-

Deliver high electrical efficiency ratings

-

Enable the job to get done right and quickly with application-specific torches and consumables/cartridges

-

Deliver productivity gains from higher operating speeds, ease of use, and superior cut quality

-

Are some of the easiest to integrate into an automated or robotic cutting system

-

Are designed, manufactured, and tested for high reliability, resulting in greater uptime and product longevity

-

These things will directly impact your total cost of ownership and result in a fast return on investment.

Profitability factor 5: plasma system configuration

If you go through the work to calculate the TCO, you should ensure the plasma system is configured correctly for your current and anticipated future needs.

When determining proper system configuration, understanding the applications the equipment is to be used for is critical. A Powermax plasma system is versatile and can perform a wide range of cutting, gouging, and marking jobs in a handheld or mechanized operation. Not all competitive systems can do this, which can impact the equipment's usage and even operator adoption if it isn’t capable of successfully performing the tasks. Talk to your dealer about your metal fabrication needs and plans for the plasma system applications. They’ll help you select the correct configuration to factor into your TCO calculations and budget plans.

Profitability factor 6: plasma cutting operator training

After you have picked the best plasma system for the job, one that’s backed by the best dealer support with the right technology to help increase efficiency, and you have it properly configured for the applications, don’t undo all that preparation by putting an untrained plasma system operator in control.

New or untrained operators can make tiny mistakes that add up quickly in material costs, maintenance costs, downtime, and overall labor costs. A few of the most common are poor operator techniques, which can result in faster than normal torch consumable/cartridge wear, damage to the metal being fabricated, and excess or unnecessary post-secondary work such as grinding.

Powermax portable plasma systems are designed with ease of use in mind, enabling a novice operator to perform like a professional in minutes. However, proper techniques for optimal performance and safety must be taught. Hypertherm Associates and our partners offer a variety of resources to help make this happen, from in-person training to online courses and tutorials through the Hypertherm Cutting Institute. Training can go a long way in reducing operator errors, ensuring that your TCO estimates are accurate, and the investment decision is wise.