Buying a new CNC plasma system – considerations beyond costs

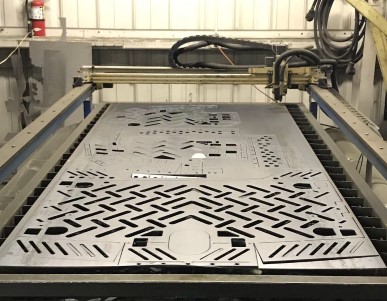

Operational expenses and productivity gains are obvious concerns when evaluating a new CNC plasma system. Faster cut speeds, fewer secondary operations, and improved material usage will all drive purchasing decisions. Likewise, the benefits of new technology will tend to offer your business improved energy efficiency, better cut quality, and longer consumable life. These considerations are important, however, here are some less obvious details that should factor into your decision.

Three questions to ask yourself when buying a CNC plasma system

When you purchase a new CNC plasma table , it is important to evaluate how the new system impacts the people involved in your business, not just the products you produce. You need to look closely at three critical stakeholders – current customers, potential customers, and your employees.

Will improving or expanding my services encourage repeat business?

Establishing a shop is already hard enough, but owners and managers depend on loyal customers and repeat business. When customers can rely on you and trust is established, loyal customers will spend more money with your shop. Moreover, your existing customers are typically easier to conduct business with because you have proven relationships. You have already demonstrated the value of your work to them.

Take the time to find out what your customers really need. They may want faster delivery times, lower costs, higher quality products, and/or customization. These are just a few ideas, but your customers will give you specific information on the ways you can improve, expand, and distinguish your shop.

Will better equipment help me keep good employees?

Loyal employees are just as important as loyal customers. Hiring and keeping good employees is one of the biggest challenges for most businesses, and each new employee requires an investment in training to get up to speed. Satisfied employees are less likely to leave your company, so evaluating any new system requires understanding the impact that system will have on your current team.

One way to increase job satisfaction is to give employees the best tools for their job. Tools that are easy to learn, make the job easier to do, and are capable of consistent outcomes help increase worker satisfaction.

Talk to your operators to find out what they want and need. Most employees care about their work and have great ideas based on their experience. By considering worker input, you will foster stronger ties and strengthen your allegiance. Even if you don't end up going with exactly what they recommend, your employees are more likely to be invested in the company's success when their needs are considered during the purchase process.

Will this machine allow me to take on new business and grow my company?

Consider the jobs offered to you in the last year. Have you turned down work or referred a customer to another shop? Have you outsourced a job, or part of a job, because you didn’t have the right tools? Were you dependent on a supplier that missed some deadlines? Are there jobs you could take on if you could cut thicker metal, cut parts with smoother edges, or bevel cut? How much are these missed opportunities costing you?

One Hypertherm client, Lyman-Morse, was able to expand their business after upgrading to a new plasma system. Lyman-Morse purchased a Hypertherm XPR300® for all the usual benefits – increased cut speed, dramatically improved productivity, and a significant reduction in operating costs. However, once they started using the XPR300, they were also able to move cutting they previously outsourced in-house and expand their business into new sectors.

“Previously, we were sending all of our materials out to a vendor to be cut. Now we are doing it all in-house using our own people, which is much better for our bottom line. And, it’s helping us to expand into other sectors that we’ve not been in before such as agricultural, aeronautical, architectural, structural, energy sector.” – Jonathan Egan, General Manager, Lyman-Morse

Fought & Company, one of the largest steel fabrication facilities in the Pacific Northwest, upgraded to automated plasma cutting using Hypertherm’s XPR300 and Rotary Tube Pro™ software for better tube and pipe cutting. The improved cut quality and increased efficiency enables them to pursue more complicated jobs without outsourcing key components, increasing their competitiveness. Fought & Company has secured and completed jobs they would not have been able to compete on before, increasing market share and profits.

“Because of the speed and accuracy, we are able to get work that normally we would not be able to get, so we have a higher market share.” – Wayne Searle, CEO, Fought & Company

Conclusion: Choose the system that best serves your customers and employees

Operational expenses and productivity gains are important when selecting a CNC plasma plate cutting machine, but you must also look beyond the cutting table. Think about the people who produce and buy your products and ask yourself how you can better serve their needs to grow your business.

Learn how Hypertherm can help you improve customer loyalty, increase worker satisfaction, and expand your business. Click the button below, fill out the form, and a Hypertherm product expert will contact you.