Torch cooling systems for plasma arc cutting

How to troubleshoot, repair, and maintain plasma cutting cooling system components

Water-cooling systems for plasma cutters are very similar to those used in automobile engines: both use water and coolant, a pump, cooling hoses, and a heat exchanger to remove energy from a heat source. In an automobile, the heat source is the combustion chamber inside the engine, which operates at temperatures in excess of 2000°F. In a plasma torch the heat source is the plasma chamber inside the torch where the temperature of the arc can exceed 20,000°F.

A plasma torch, like an engine, is cooled by a combination of radiation, convection, and conduction. Energy radiates from the arc in the form of intense ultraviolet rays. Heat convects away from the torch and torch parts through moving gas or air. And finally the water-cooling system conducts heat away from the torch parts into the coolant.

What happens when conductive cooling is reduced because of a problem with a component in the cooling system? The system overheats rapidly. Anyone who has overheated an automobile knows the inconvenience of being stranded on the side of the road with a steaming vehicle and the expense of cascading repairs that typically follows such as new radiators, hoses, head gasket or even engine block. When the plasma system overheats it will also cost you time and money. An overheating plasma system will wear out torch parts quickly and eventually may burn out the torch and leads. If the problem goes uncorrected, a motor and pump may have to be replaced. But the downtime and expense of overheating can be avoided. Understanding the system and its components will help you troubleshoot problems when they occur and prevent future failures through preventative maintenance.

Plasma cutting cooling system components

The cooling system

A typical plasma cutting cooling system consists of a torch, motor, pump, cooling lines, flow switch, filter, heat exchanger and reservoir. This article will go over each of these components and describe common problems, troubleshooting and maintenance procedures.

Plasma torch

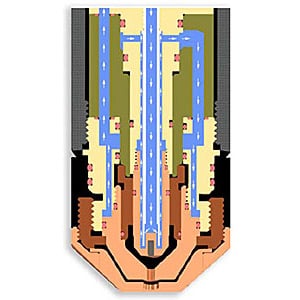

Plasma torches that operate at 100-150A and higher (15kVA) require water-cooling to keep the torch and parts from overheating. Figure 1 is a cross-section view of a plasma torch showing the internal passages for cooling water. The copper electrode generates the plasma arc and is closest to the heat source so it requires direct cooling. Most high power electrodes are hollow milled to allow for improved cooling at the tip: a water tube extends into this milled area, closely spaced and precisely aligned to the electrode (usually .015"-.020" clearance per side), and provides a high flow velocity of coolant over the interior rear surface of the electrode. In this torch design, the nozzle is also cooled by water.

Common problems with torches:

- Clogged torch: Torches can clog up over time with particulate. Particles of melted copper from failed electrodes can plug small holes and reduce or cut off water flow.

- Damaged water tube: If the water tube is bent, damaged on the end or not threaded into the torch properly, it will reduce cooling water flow.

- Leaky torch: Damaged o-rings or o-ring sealing surfaces can cause leaking of the cooling fluid. Tubes and fittings at the back of torch may weep coolant causing low tank levels.

Figure 1 - Plasma torch cooling passages

Figure 1 - Plasma torch cooling passages

|

Figure 2 - Torch coolant |

Coolant

Torch coolant is a mixture of de-ionized water and ethylene or propylene glycol to depress the freezing point. Many shops use plain de-ionized water if there is no risk of freezing. De-ionized water must be used because it is free of conductive ions that can cause problems in the system. Ethylene or propylene glycol is the same agent used in automotive cooling systems. However automotive antifreeze should never be used in a plasma system! Most commercial antifreeze has material in it to clog small leaks. This makes it unsuitable for use in a plasma torch.

Common problems with coolant:

- Contamination: Over time coolant can become contaminated by bits of hose, wire, or copper from failed parts, dirt, rust, algae or other contaminants. These contaminants reduce the cooling efficiency and lower the flow rate. Flushing of the system, a new filter, and new coolant may be required.

- Conductivity too high: If the conductivity of the coolant is too high, or conversely if the resistivity is too low, electricity may conduct through the cooling water in the torch. This can cause hard starting of the plasma arc when the torch is striking an arc between electrode and nozzle. Even new coolant not made to the manufacturers specification may not meet the conductivity requirements of the system. It is best to use OEM coolant or periodically test the coolant conductivity using a special tester, the recommended level is between .5 and 18micro Siemens/cm. (see Figure 3)

Figure 3 - Measuring conductivity of coolant

Pump motor

Typically motors and pumps in plasma systems are directly coupled. The service life of a motor is usually quite long (several years) unless there are restrictions in the system causing the motor and pump to work harder.

Rotary vane pumps are most often used in plasma systems because they are relatively simple and robust. They are often called carbon vane pumps since the moving vanes of the pump are made of a carbon material. These pumps are usually adjustable via a bypass screw that increases or decreases the operating pressure and flow of the pump.

Common problems with pumps:

- Normal pump wear: Some wear of the carbon vanes is normal due to friction and heat from constant use. Adjusting the pump can compensate for this condition.

- Excessive pump wear: Bearings in these pumps may eventually wear out causing excessive noise and heat, and ultimately pump failure. The material in the pump vanes can become worn down until the pump will no longer develop pressure. These parts can usually be replaced if the pump is sent in for a factory recondition or the pump may need replacement.

- Clogged pump filter: There is a small screen filter in most rotary vane pumps. This filter may clog with particulate causing a flow restriction.

Figure 4 -

Adjusting pump pressure

Figure 5 -

Carbon vanes in pump

Figure 6 -

Removing pump screen

Cooling lines

Cooling lines are hoses that carry coolant to and from the plasma torch. These usually contain the main DC power cables as well. Water-cooled power cables prevent the multi-stranded copper or tinned copper wire from overheating. In mechanized applications, cooling lines are usually routed through flexible power track or festooned above the cutting machine.

Common problems with cooling lines:

- Leaks: Cracked, cut, or melted hoses may leak cooling fluid in areas that cannot be seen. A common spot for a leak is just above the torch inside the mounting tube.

- Restrictions: Flow restrictions most commonly form in the return line from the plasma torch to the re-circulator. Debris accumulates in return leads restricting flow. The tinned copper power cables can also break down from constant flexing allowing filaments of copper to clog up the ends of the hoses. Restrictions in the leads cause reduced flow and increased wear on the pump and motor.

Figure 7 - Hose cutaway to show power cable

Flow switch

Flow switches are designed to prevent catastrophic failure of the torch and parts in the event of low coolant flow. Brass block plunger type devices are typically used with a micro-switch that must be satisfied for the system to run.

Common problems with flow switches:

- Mechanical failure: coolant flow actuates a mechanical plunger. The plunger can stick in the open or closed position causing a fault condition or no fault even in low flow conditions. The mechanical portion may sometimes be removed and cleaned but it is best to replace.

- Electrical failure: Failure of the electrical switch is much less common but may occur if switch contacts wear out.

- "Jumpered" out: It is not uncommon to find flow switches "jumpered" out of the system from previous troubleshooting. This is a dangerous practice since the flow switch is the safety feature that prevents a major torch failure due to overheating.

Figure 8 - Flow switch

|

|

Filters

Most systems use a particulate filter to remove contamination from the torch coolant. These filters are similar to commercially available water treatment filters—usually a 5-micron paper filter or de-ionizing filter is used. These should be changed every few months or whenever flow in the system is reduced.

Common problems with flow filters:

- Contaminated filter

- Incorrect filter or no filter

Heat exchangers

Figure 10 - Heat exchanger front and back views |

Heat exchangers for plasma cooling systems usually consist of a radiator and fan combination. Fans direct airflow through the radiator to remove heat from the torch coolant. Some systems use a refrigerated chiller to cool the torch coolant.

Common problems with heat exchangers:

- Fan motor burnout: All fans should be checked periodically to make sure they are performing.

- Reduced efficiency: Dirt buildup on the cooling fins reduces the cooling efficiency. The radiator should periodically be cleaned using compressed air.

Coolant reservoirs

|

Figure 11 - Coolant reservoir with level and temperature switches |

The coolant reservoir is a plastic or metal tank for holding the torch coolant. Level indicators, float switches, and temperature switches are usually installed in the tank for to prevent overheating. The coolant reservoir should be checked daily and topped off as necessary to make sure there is always adequate supply of coolant. If coolant levels are too low, air may be introduced into the coolant stream, which reduces cooling. If the system is interlocked low coolant may cause intermittent or total shut down. If the system is not interlocked, air may cause the pump to overheat and fail.

Common problems with coolant reservoirs:

- Particulate contamination: Particulate may accumulate in the bottom of the tank. This should be flushed out and removed. The tank may need to be removed and steam cleaned periodically.

- Inadequate coolant level.

System troubleshooting

|

Figure 12 - Liquid flowmeter |

The individual components in the plasma cooling system are all designed to ensure one thing: an adequate volumetric flow rate to the torch for cooling. Flow is typically measured in gallons per minute (gpm) or liters per minute (lpm). Each torch has a specific flow requirement that can be found in the specifications section of the operator's manual. Typical flow rates are 1 to 1.5 gallons per minute. Here is a step-by-step approach for verifying proper coolant flow and troubleshooting flow problems.

CAUTION! Always read your operator's manual and understand all safety precautions before performing maintenance and troubleshooting on a plasma system.

- Remove torch parts: When troubleshooting, begin at the torch. Remove the consumables and inspect them for signs of overheating, contamination, or damage.

- Turn on coolant pump. (You may need an assistant to keep the pump running during flow measurement and to top off the coolant level if it gets low.) Coolant should flow directly out of the center of the cooling tube in the torch.

- Measure coolant supply flow to torch: Use a bucket to catch coolant that is discharged from the cooling tube. Collect coolant over a time interval of 30 sec then shut off the pump. Measure the volume of coolant in gallons or liters. Convert this volume to a flow rate by dividing gallons collected by the time interval (.5 minute) to attain gallons per minute (gpm) or liters per minute (lpm) Compare this measurement to the specified flow rate in the operators manual. The flow in an unrestricted torch (without parts in it) should far exceed the manufacturer's spec. If it does not, check the following:

- Pump pressure too low—adjust pump setting.

- Screen filter in pump restricted—clean.

- Supply line to torch or torch restricted—blow out debris with compressed air or replace.

- Re-assemble torch: Using clean new parts, reassemble the torch. Parts must be in place for a proper flow check

- Measure the coolant return flow from torch: Coolant flow rate must be measured at the return to the coolant reservoir. Disconnect the plastic hose from the coolant tank. Again, use a bucket and an assistant to collect water for a 30-second interval then shut off the pump. Convert the measurement to gpm. Compare this flow rate to the manufacturer's specification. If the gpm does not exceed the manufacturers spec check for the following:

- Pump pressure too low—adjust pump setting.

- Return coolant line or torch restricted—blow out debris with compressed air or replace.

- Radiator plugged—use high-pressure washer to clean or replace.

- Paper filter restricted--replace or remove temporarily for troubleshooting.

If necessary, flow may be checked on the downstream side of each suspect component until a restriction is found. An alternative to the bucket test is to purchase an inexpensive flow meter designed for liquid flow measurement in the range of 0-2 gpm. This simple device may be permanently installed in the return side of the system at the reservoir. It is a great visual tool for maintaining the plasma system and cheap insurance against a costly breakdown.

Figure 9 - Coolant filter

Figure 9 - Coolant filter