Improve plasma cut quality with these CNC steel and metal cutting tips

The following plasma cutter tips offer several solutions to help improve cut quality on metal plate. These plasma cutting tips are designed to work when cutting metal on a CNC plasma cutting table. Whether the job calls for mild steel cutting, stainless steel cutting, aluminum cutting, or some other type of metal, it is important to try and work through the troubleshooting suggestions provided to improve cut quality– as often there are many different factors to consider. The factors considered by these plasma cutting tips include:

-

Type of cutting machine (e.g. X-Y table, punch press, motorized track, robot)

-

Plasma cutting system (e.g. air plasma cutter, oxygen plasma, high definition class plasma, power supply amperage (amp))

-

Motion control device (e.g. capability of the CNC machine and torch height control)

-

Process variables (e.g. cutting speed, cut height, standoff, cut path, choice of consumables)

-

External variables (e.g. material variability, gas purity, operator experience)

It is important to consider all of these plasma-cutting factors when attempting to improve poor cut quality

Step 1: Is the plasma arc cutting in the appropriate direction?

When CNC steel cutting, the most square cut edge angles are always to the right side, with respect to the forward motion of the torch.

-

Check the direction of the cut

-

Adjust the cutting direction by changing your plasma cutting settings, if needed

The plasma arc typically spins clockwise with standard consumables.

Contour:

-

Torch travels clockwise

-

Good side of the cut is to the right side of the torch, as it travels forward

Internal feature (hole cutting):

-

Torch travels counterclockwise

-

The "good side" of the cut is to the right side of the torch, as it travels forward.

Plate with internal hole

Step 2: Was the correct process or CNC plasma cutter settings selected for the material and thickness being cut?

Refer to the cut charts in the operation section of the Hypertherm Instruction Manual.

Be sure to follow the plasma cutter settings and specifications in the cut charts. It is critical that these plasma cutter settings are correct:

-

Select the appropriate plasma cutting setting process for:

-

Material type

-

Material thickness

-

Desired cut quality

-

Desired bevel angle

-

Productivity goals

-

-

Select the correct plasma and shield gas if using a dual-gas plasma cutting system

-

Select correct cutting parameters or plasma cutting settings for:

-

Gas pressures (or gas flow rates)

-

Torch-to-work distance and arc voltage

-

Cutting speed

-

-

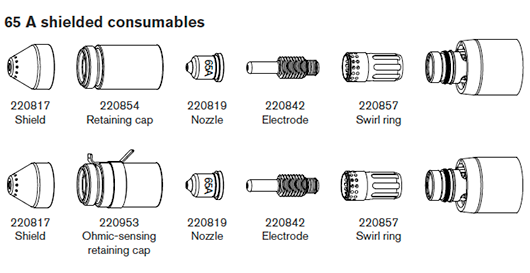

Confirm the correct consumables (tips) are being used and verify the part numbers

Note: Generally, lower amperage cutting processes offer better angularity and surface finish; however, cutting speeds will be slower and dross levels will be higher.

Step 3: Are the plasma consumables worn?

-

Consumable life is an important factor

-

Inspect plasma consumables for wear

-

Replace worn consumables

-

Always replace the nozzle and electrode at the same time

-

Avoid over-lubricating O-rings

Note: Use genuine Hypertherm consumables to ensure maximum cutting performance.

Step 4: Is the torch square to the workpiece?

- Level the workpiece

- Square the torch to the workpiece (both from the front and side of the torch)

Note: Check to see if material is bent or warped; in extreme cases this limitation cannot be corrected.

Step 5: Is the torch-to-work distance set at the proper height?

-

Adjust torch-to-work distance to the correct setting

-

If using arc voltage control, adjust the voltage

Note: As consumable parts wear, arc voltage settings need continual adjustment to maintain torch-to-work distance.

The torch-to-work distance can impact angularity

Negative cut angle: plasma torch too low; increase torch-to-work distance

Positive cut angle: plasma torch too high; decrease torch-to-work distance

Note: A slight variation in cut angles may be normal, as long as it is within tolerance.

Step 6: Is the cutting speed set too fast or too slow?

- Adjust cutting speed, as needed

Note: Cutting speed may also impact your dross or molten metal levels.

High-speed dross: Cutting speed too fast (arc lags behind), reduce cutting speed

Low-speed dross: Cutting speed too slow (arc shoots ahead), increase cutting speed

Top spatter: Cutting speed too fast, reduce cutting speed

Note: In addition to speed, both material chemistry and surface finish can impact the amount of molten material; as the workpiece heats up, more dross may form on subsequent cuts.

Step 7: Are there problems with the gas delivery system?

-

Identify and repair any leaks or restrictions

-

Use properly sized regulators and gas lines

-

Use pure, high-quality gas

-

If a manual purge is required, such as with the MAX200, confirm the purging cycle was completed

-

Consult the gas distributor

Step 8: Is there torch vibration?

-

Make sure that the torch is secure to the table gantry

-

Consult OEM; table may require maintenance

Step 9: Does the plasma cutting table need to be tuned?

-

Check and ensure that the table is cutting at specified speed

-

Consult OEM; table speed may need tuning

Following these CNC plasma cutting tips will help ensure you get the best performance and cut quality every single time helping you produce better metal parts.

Looking for plasma consumables information?

-

Plasma cutter consumables for Powermax® and MAX plasma cutters

-

Plasma cutting consumables for non-Powermax automated plasma systems