The quality of the XPR300® cut is the very best that I’ve seen. It’s helping us to expand into other sectors such as agricultural, aeronautical, architectural, structural, and energy.”

Lyman-Morse

Read more

Provided by the best partner network in the world, Hypertherm XPR® helps hundreds of thousands of businesses maximize power and optimize productivity.

Hypertherm is the world’s #1 requested plasma brand, trusted by more businesses and metal fabricators than any other. XPR powers your profitability and pays you back with maximum versatility, productivity, and precision.

Unmatched X-Definition® plasma technology delivers consistent cut quality, thicker cutting capability, faster cutting speeds, and longer consumable life.

12%

Up to 12% faster cutting speeds on mild steel than other 400A processes

25%

Gain a 25% increase in piercing capability with our industry-exclusive argon-assist technology

3x

Extend consumable life up to 3x with Exclusive Arc Response Technology™

“When the new XPR460 arrived, it was a miracle in terms of piercing. Now, we pierce and go on a 2″ plate without sacrificing cut quality. It’s a huge productivity improvement.”

R&T Mechanical

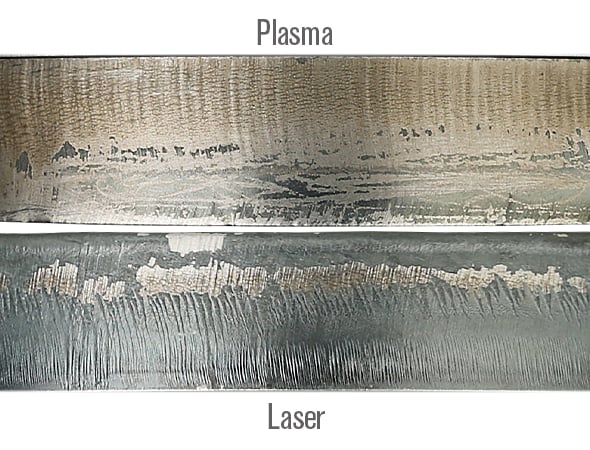

Plasma excels across various material thicknesses and is especially advantageous when cutting metal over 16 mm (5/8″).

Plasma cutting is faster, has a lower initial investment and direct operating cost, and is more forgiving on imperfect or reflective metal.

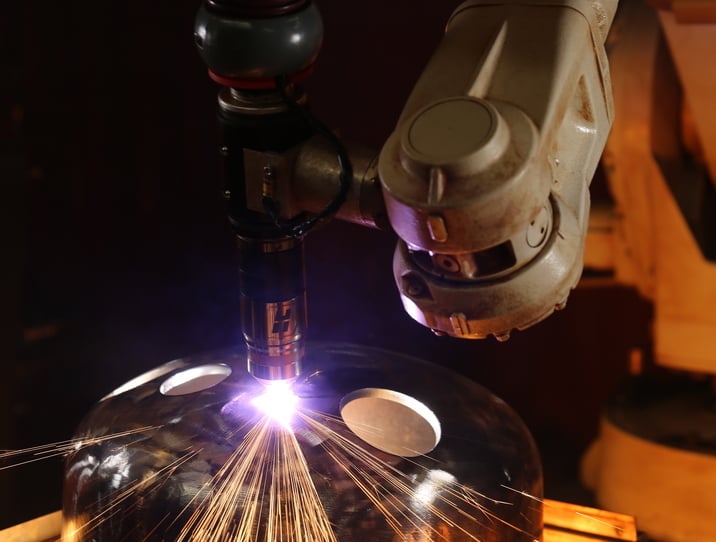

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

Many fabrication processes require cutting holes to bolt two or more pieces or parts together, so hole production is an important part of most cutting operations. Multiple holes can be cut into a large plate, pipe, or drum with plasma.

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.