We’ve used the PlateSaver technique on several nests already, and we’re seeing better material optimization rates, especially with thicker, rectangular parts.”

Plasma Cutting Services

Plasma, PlateSaver

Read moreProNest® CAD/CAM part nesting software for advanced mechanized cutting is designed to supercharge your cutting operation, helping you achieve greater automation, efficiency, and profitability. Brought to you by the cutting experts at Hypertherm, ProNest can optimize performance for plasma, laser, waterjet, and oxyfuel cutting machines.

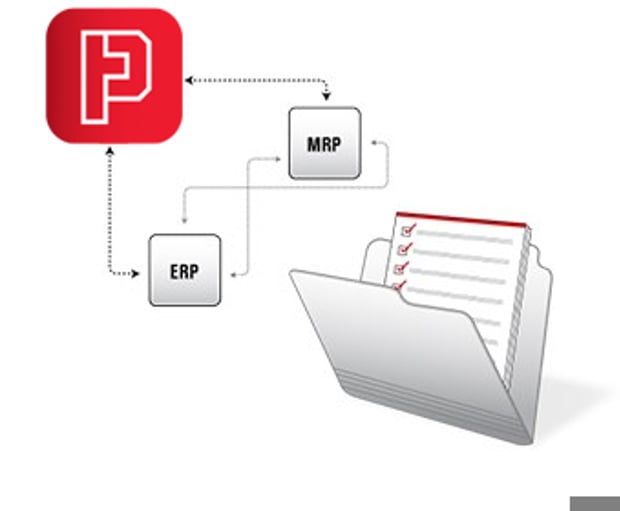

Improve efficiency and productivity by integrating ProNest with your ERP/MRP/MES system. What were once manual and redundant tasks can now be queued, tracked, and combined more easily. And inventory will be better managed for faster turnover and reduced waste. All of which adds to your profitability.

|

CPU |

1.4 GHz processor or faster |

|

Memory |

8 GB RAM (16 GB recommended) |

|

Display |

VGA display with at least 256 colors and a resolution of 1024 x 768 |

|

Disk space |

6 GB available disk space |

|

Microsoft® Windows® operating system |

Windows 11, Windows 10 (64-bit OS only) |

|

Spreadsheet program |

Microsoft Excel® 2010 or later is recommended for editing ProNest settings spreadsheets. |

| Browser

|

Supported browsers for the ProNest Server web app:

Note: Internet Explorer and Microsoft Edge Legacy are not supported. |

ProNest or LT: Which one do I need?

Check out our comparison chart