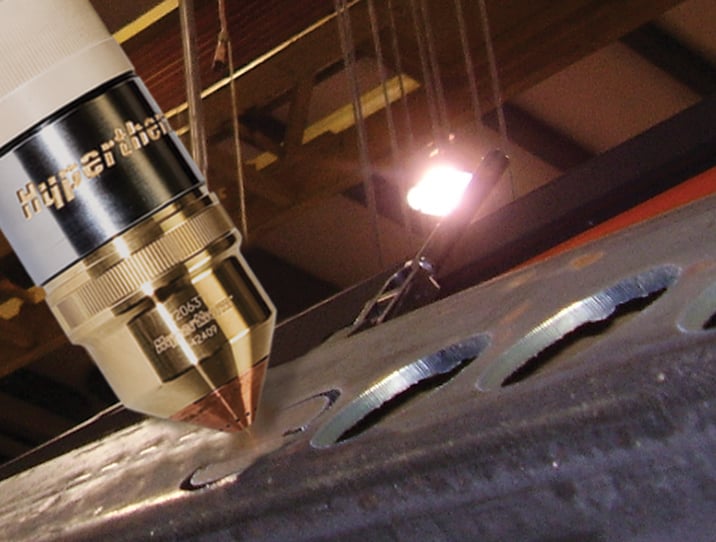

Wind turbines, nuclear power plants, pipelines, and pressure vessel are some items the energy industry manufactures with Hypertherm plasma products. In addition, plasma is used to construct and repair power lines, pipelines, and company trucks.

Manufacturers choose Hypertherm because its products and solutions are designed to address the biggest pain points and challenges these companies face:

Increasing costs for both raw materials and labor

Severe shortage of skilled labor

Strict environmental compliance regulations

Cost pressure from increased competition

Bottlenecks created by need for secondary operations

X-Definition® and high-definition plasma deliver improved cut quality and faster cut speeds which reduces time consuming secondary operations and increases throughput so energy companies can meet delivery deadlines. True Bevel™ technology produces repeatable and accurate bevels with no trial and error while PlateSaver™ maximizes parts per plate so fewer plates are needed.

Air plasma is used for its portability and ability to cut metal in remote locations under adverse conditions. Requiring no high pressure or flammable gases, air plasma offers a much safer option than oxyfuel. In addition, FlushCut™ consumables designed for use with Hypertherm Powermax® plasma makes maintenance jobs easier by reducing post-secondary grinding. Products like the new Powermax SYNC® with its single-piece consumable cartridge and smart data collection significantly cuts down on training needs and operator errors.

Our software, from ProNest® to Robotmaster®, delivers incredible ease of use and embedded expertise which reduces training time and labor.

Typical uses by the energy industry include: