Thanks to these automatic machines we are also able to increase the capacity to our desired target of 300 tons of production per month.”

EXCON

Structural steel

Read moreThe XPR® plasma family raises the bar on mechanized plasma cutting, delivering X-Definition® technology that significantly enhances the capability of Hypertherm’s HyDefinition® and HyPerformance® (HPR) processes delivering substantial gains in cut quality on mild steel, stainless steel, and aluminum applications. XPR boosts cut speed, enhances productivity, and reduces operating costs.

Improves cut quality and consistency (cut angularity) through the life of the consumables

Delivers superior cut quality for cutting stainless steel and cutting aluminum across the thickness ranges providing cleaner, sharper, and more consistent edge quality

XPR advanced arc response technology automatically intervenes to certain events that can lead to decreased consumable life or possible torch damage.

Automatic torch protection prevents catastrophic torch failures caused by overusing the electrode

Automatic ramp-down error protects the electrode’s life by automatically applying a controlled stop of the plasma process when the arc is over-stretched

The web interface tool can be accessed via WI-FI and Ethernet LAN in the power supply for system monitoring and service

Built-in IIoT via Ethernet LAN and MTConnect® enables remote data access for smarter monitoring from anywhere in the world

Manual Set-Mode is ideal for straighforward applications like gouging and off-table beveling

Dramatic improvement in consumable life on mild steel applications

Fast cutting speeds and consistent high-quality outcomes reduce labor required to process cutting with XPR

Type of metals being cut and expected quality outcomes will determine what gas console better fits your needs.

Type of metals being cut and expected quality outcomes will determine what gas console better fits your needs.

The Core console is designed for customers that cut mostly mild steel. The Core console offers full X-Definition capability on mild steel and entry-level capability on stainless steel and aluminum through the use of nitrogen as its plasma gas. The Core is capable of marking with nitrogen plasma gas on all materials.

The CorePlus console is designed for customers that cut mostly mild steel. Like the Core, the CorePlus console offers full X-Definition capability on mild steel and entry-level capability on stainless steel and aluminum through the use of nitrogen as its plasma gas. This includes very good results on thin stainless steel through Hypertherm’s HDi cutting process. The CorePlus is capable of marking with argon plasma gas on all materials and provides thicker material piercing using argon-assist technology.

The VWI console is designed for customers whose volume is predominantly mild steel but who require improved capability for cutting stainless steel and aluminum, thicker piercing capability, or high-quality marking. The VWI console offers all the benefits of the Core console plus:

Patent pending VWI processes which utilize a water-injection shield yielding excellent cutting outcomes on stainless steel and aluminum

F5 fuel gas capability delivering superior results on thinner stainless steel compared to nitrogen cutting

Argon gas capability offers exceptional marking results and increased pierce thickness capacity when using argon-assist cut processes

The Optimix console is designed for customers that cut a high volume of stainless steel and aluminum and who require the highest cutting outcomes for these applications. The Optimix console offers all the benefits of the VWI console plus the ability to mix up to three discrete gases:

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

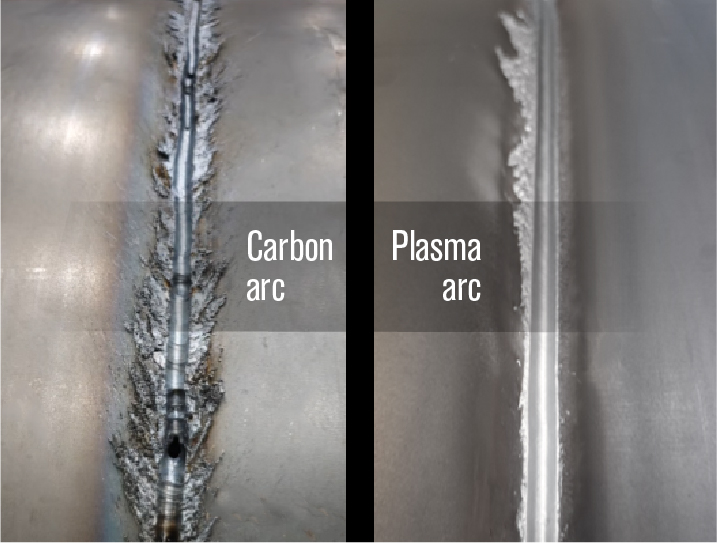

XPR automated gouging capabilities are redefining weld prep for large-scale fabrication. By delivering wider, deeper, and cleaner gouge profiles, XPR virtually eliminates the need for grinding compared to carbon arc gouging.

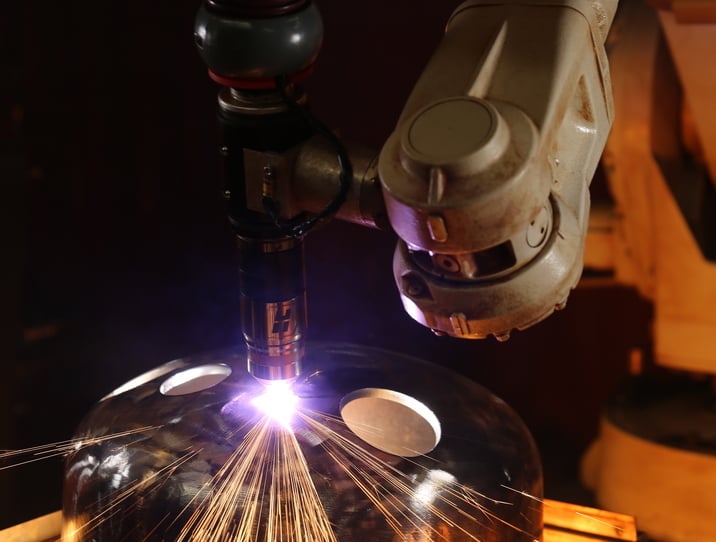

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.