About True Hole technology

Since its initial release, True Hole® technology has become a mainstay for those who demand high-quality bolt ready holes. Historically, machine operators had difficulty achieving good hole quality directly off the plasma cutting table, with drilling often required as a secondary process. True Hole technology—a patented process for mild steel that virtually eliminates hole taper and improves roundness—produces significantly better hole quality than what was previously possible using plasma.

Key business benefits

-

Improves hole quality automatically

Bolt hole quality is delivered without operator intervention -

Competes with laser hole quality

Improved hole quality makes plasma suitable for many jobs previously cut with laser -

Increases productivity

Reduces the need for secondary processes and completes jobs in fewer steps

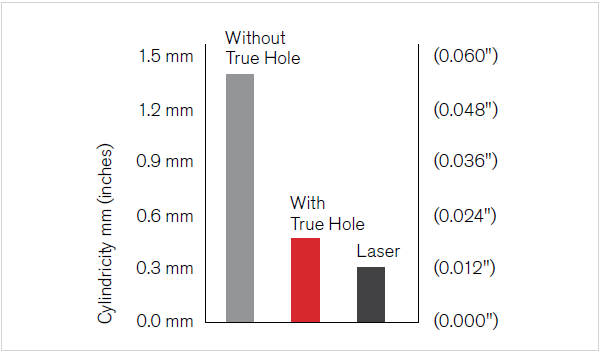

True Hole eliminates taper and improves roundness

Hole cylindricity

Example based on 0.394" holes, 3/8" mild steel plate, 130 A process

CAM software or CNC automatically applies True Hole technology

Specific combinations of the following parameters, which may vary based on amperage, material type, thickness, and hole size are applied to the job:

-

Process gas type

-

Gas flow

-

Amperage

-

Piercing methodology

-

Lead in/lead out technique

-

Varying speeds across multiple hole segments

-

Arc termination synchronized with torch motion

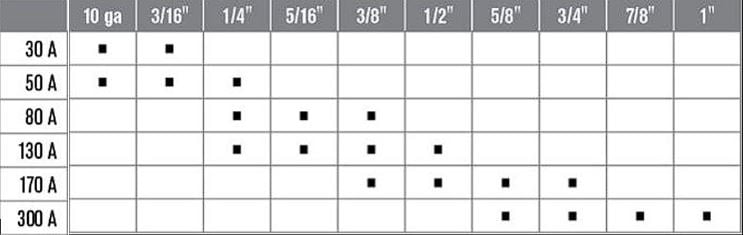

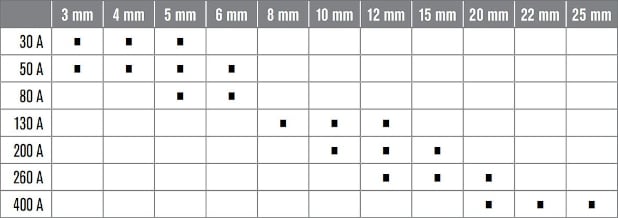

XPR - True Hole processes by thickness

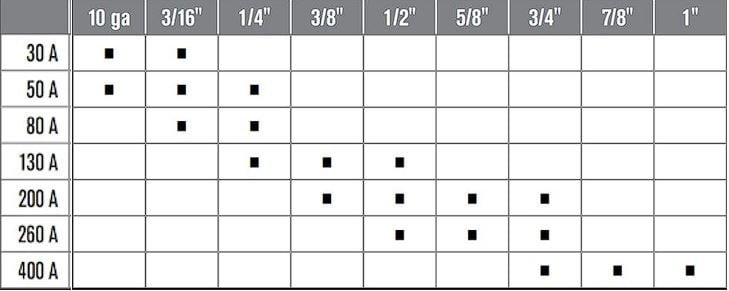

HPR - True Hole processes by thickness

System requirements

-

For use with mild steel, up to 25 mm (1")

-

Applies to holes where the diameter-to-material thickness ratio ranges from 2:1 to 1:1

-

Hypertherm XPR® X-Definition® or HPRXD® plasma system

-

ProNest®, EDGE® Connect, or other CAM or CNC software from an authorized partner

-

Not recommended for water tables where the water level is at or above plate surface

Where to buy a True Hole-capable machine

For assistance finding an authorized Hypertherm partner in your area, please use the contact form below and be sure to specify your interest in True Hole.

Related content

XPR family cutting solutions

The XPR® plasma family represents the most significant advancement in mechanized plasma cutting technology, ever.