About True Bevel technology

Bevel cutting is a complex process that typically requires trial and error, forcing machine operators to make multiple test cuts to determine the correct bevel angles for each new part. This costs precious time and money. True Bevel technology for mild steel provides factory-tested parameters, making it quick and easy to set up new jobs. With True Bevel, you can achieve accurate bevel parts and consistent results in significantly less time.

Key business benefits

-

Improves the beveling process

Automatically applies improved bevel angle and cut sequence, increasing accuracy and quality consistency -

Saves time and money

Setup time and scrap material are significantly reduced due to lessened operator trial and error

Field testing with True Bevel

Without True Bevel

Parts took over one hour to complete using existing iterations and required one or more additional iterations to obtain an acceptable part.

With True Bevel

True Bevel achieved a production-ready,

acceptable part on the first iteration.

CAM software or CNC automatically applies True Bevel technology

Predetermined bevel angles, equations, and recommended sequences are applied to the job based on amperage and material thickness.

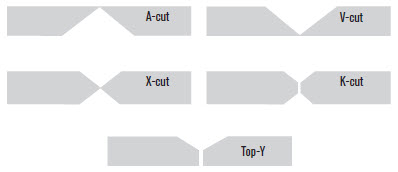

Cut styles include:

Cut styles include:

- A-cut

- V-cut

- X-cut

- K-cut

- Y-top

Thickness coverages

To review the material thicknesses, cutting amperages, angles, and lands covered by True Bevel technology, please download the appropriate data sheet.

System requirements

-

For use with mild Steel

-

Hypertherm XPR® X-Definition® or HPRXD® plasma systems

- ProNest®, EDGE® Connect, or other CAM or CNC software from an authorized partner

Where to buy a True Bevel capable machine

To find an authorized Hypertherm partner in your area, please use the contact form below and specify your interest in True Bevel.

Where to buy

Related content

XPR family cutting solutions

The XPR® plasma family represents the most significant advancement in mechanized plasma cutting technology, ever.